HiMON® – Modular measuring and condition assessment system for fast localization of cable breakdowns and evaluation of partial discharges

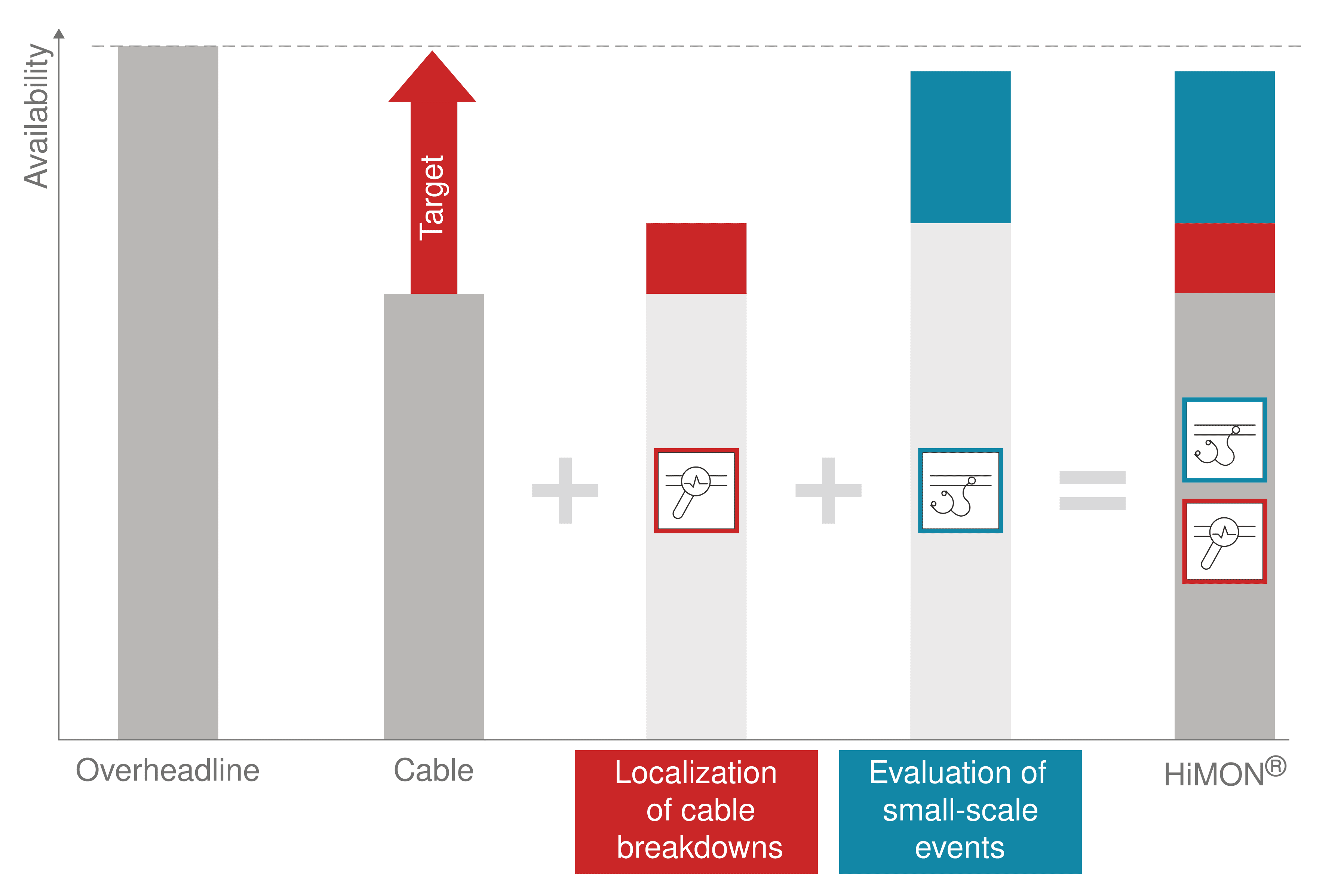

Availability comparision of transmission lines

(Approximate availability depends on cable length)

Underground cable

95 %

Subsea cable

92-97 %

Overhead line

> 99 %

How to increase availability of cable transmission lines?

Condition assessment during factory testing, commissioning and operation

Fast localization of cable breakdowns

Detection of oncoming faults

Evaluation of aging

Increase in availability for cable systems

Target: Reduce 30 % of repair time

Target: 70 % of faults are found in advance, so they can be repaired during planned shutdowns.

HiMON® makes the availability of cable systems comparable to that of overhead lines.

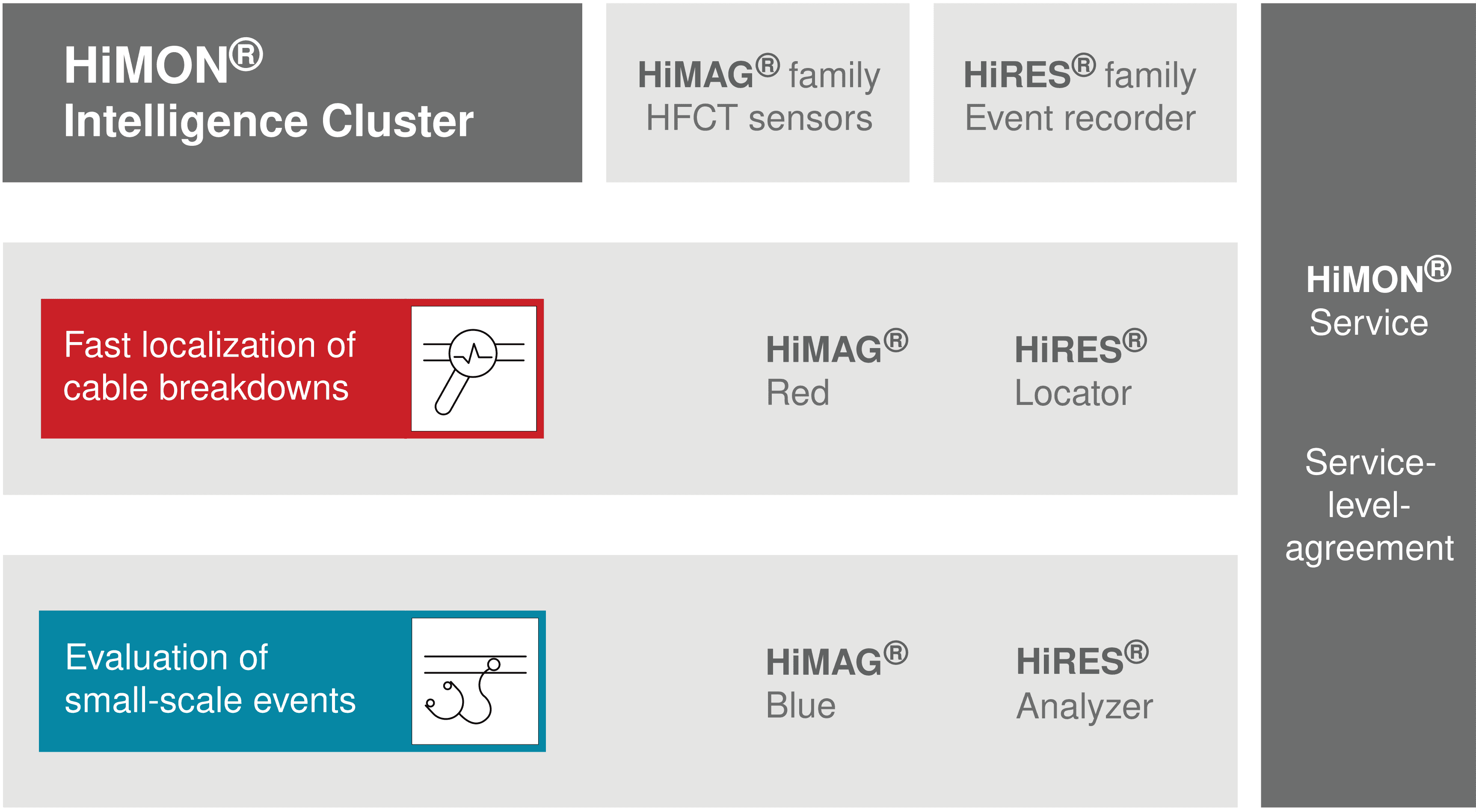

Product and service overview

Methods

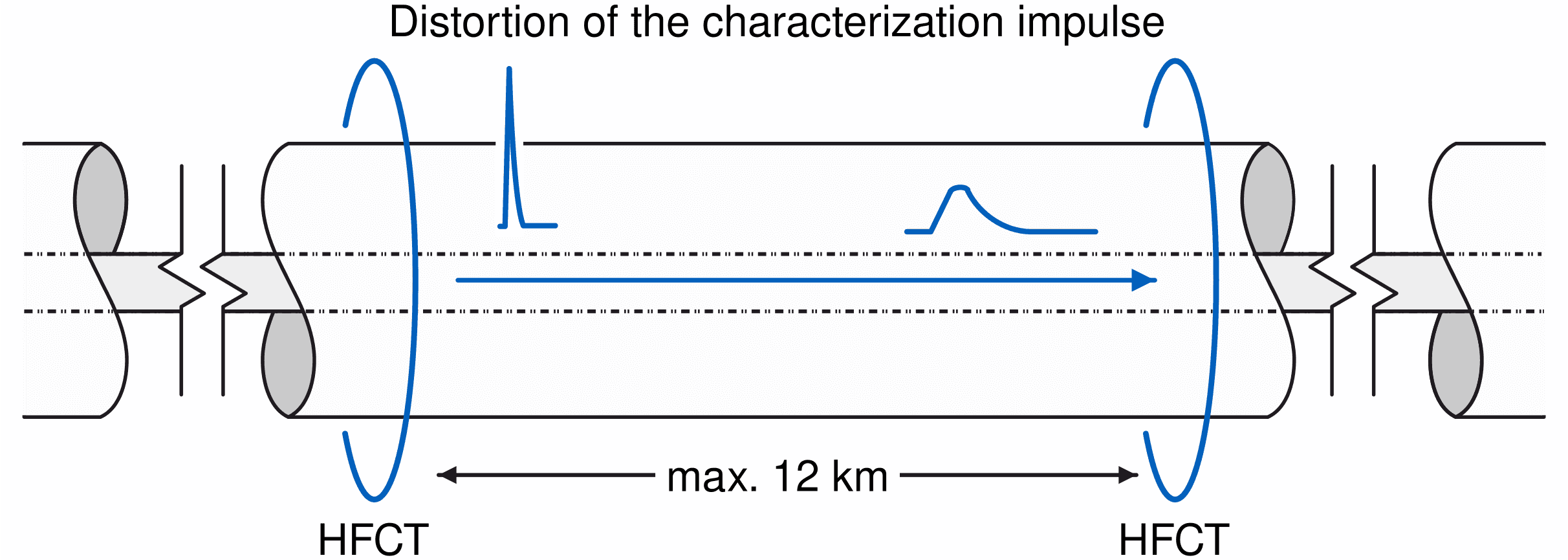

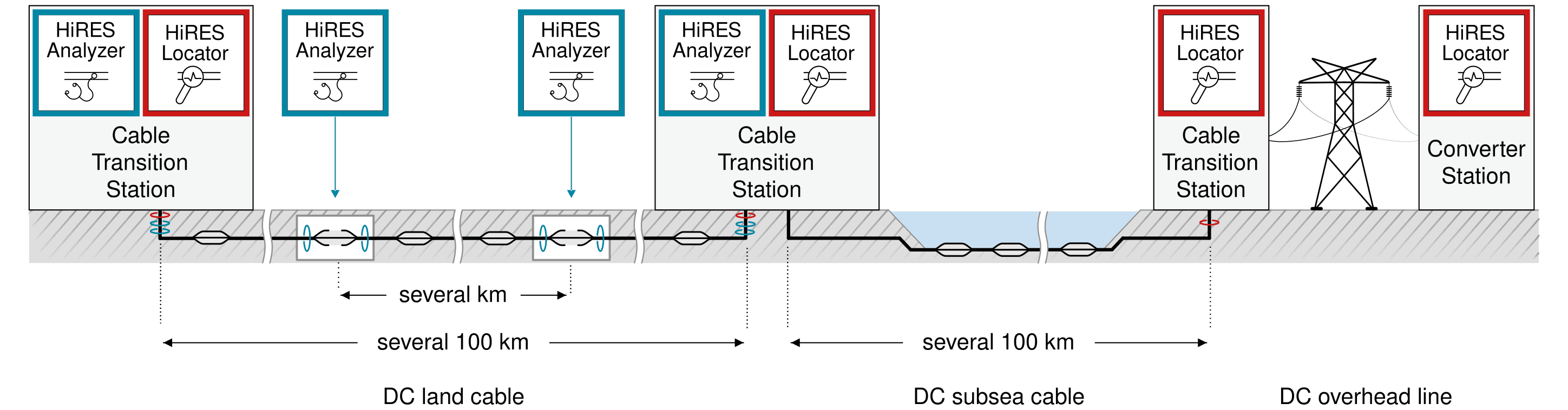

RT-TF Analysis and synthesis of all cable sections

Periodic modelling of a cable section between two sensor units. Injection of small impulses into the cable in order to determine the transfer function of the cable section

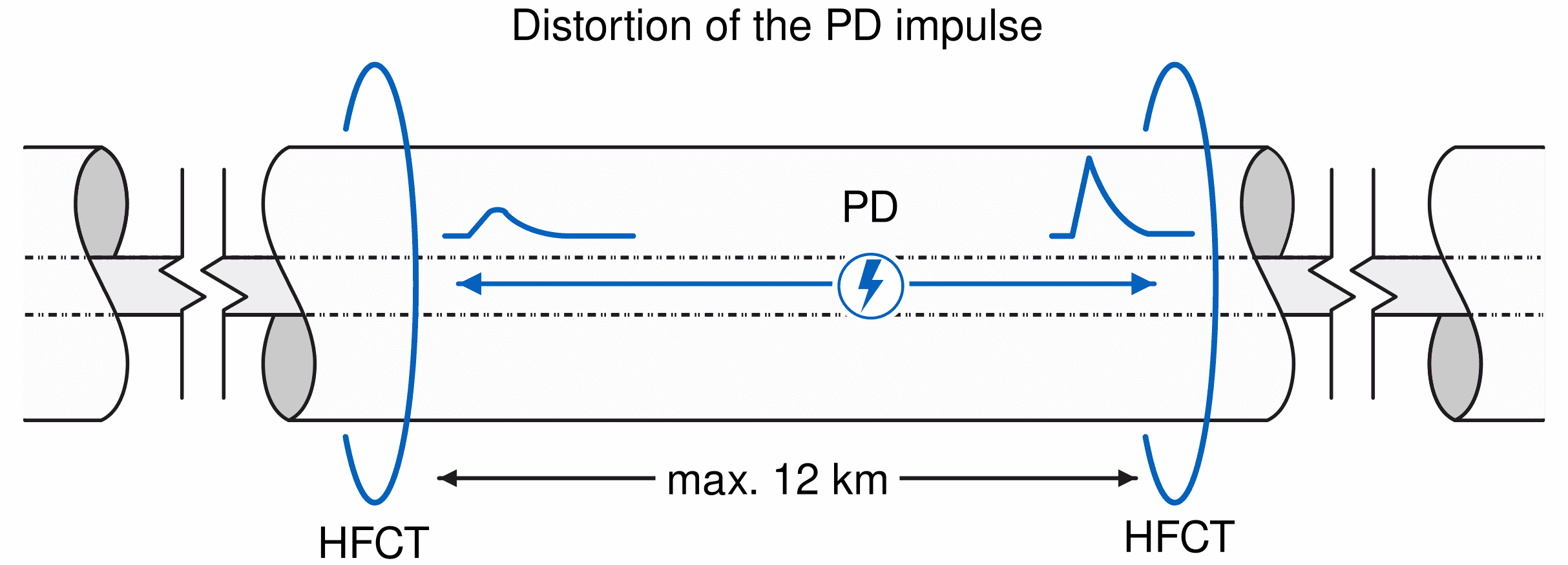

TruePD Measurement and filtering of real signals

Localization and determination of detected partial discharges at the location of the fault under consideration of the actual cable transfer function. Classification and characterization of the events with AI algorithms.

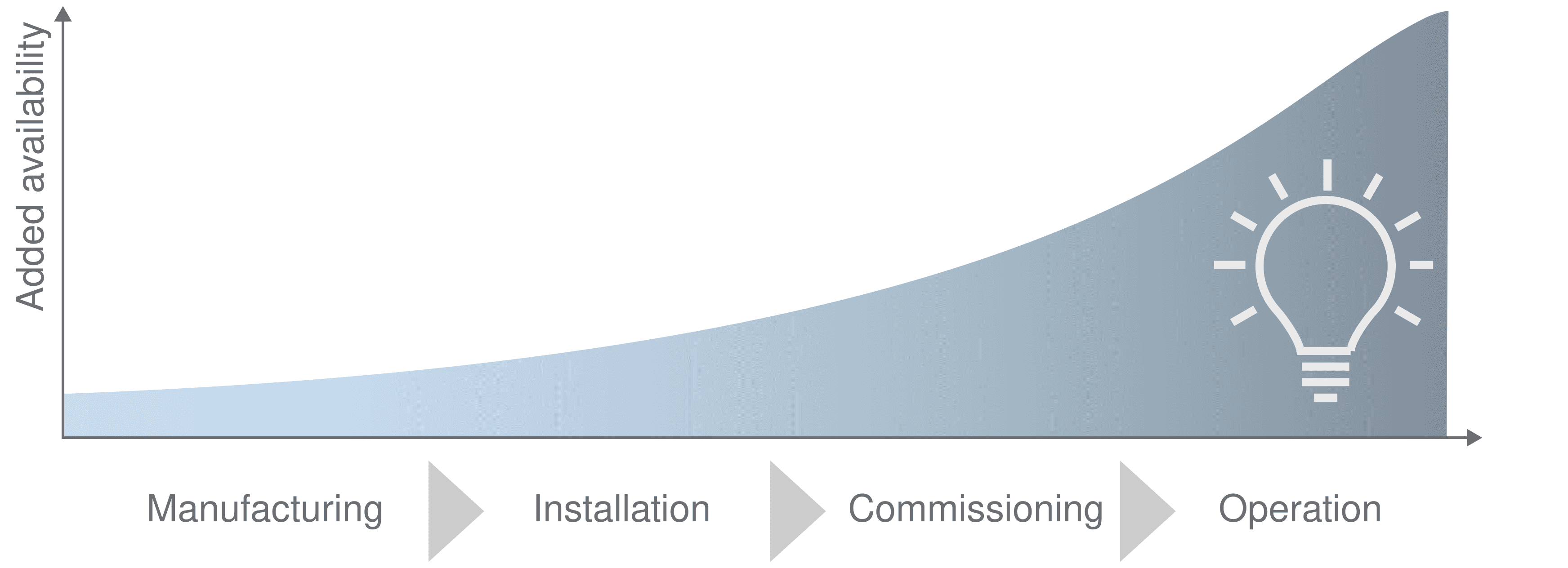

Added availability of transmission systems functions

Manufacturing

Fast localization of cable breakdowns

Quality assurance (PD) for joints/cables

Installation

Theft monitoring for the cable system

Quality assurance (TF) during on site joint installation

Commissioning

Fast localization of cable breakdowns

Quality assurance (PD) for joints/cables

Operation

Fast localization of cable breakdowns

Small scale event evaluation

Risk analysis

HiMON® increases the availability through combining functions in every phase of a cable lifespan

System integration

Installation of measuring points every 12 km is worldwide unique

Calculation of downtime cost savings

in km

in MW

in EUR

Annual downtime cost

73,920,000 €

Without HiMON®15,523,200 €

With HiMON®Availability

90.36 %

Without HiMON®97.97 %

With HiMON®HiMON® helps saving significant amounts of downtime costs

Benefits

HIGHVOLT is neutral

Reduction of downtime costs

Increase of availability

Suitable for new and existing cable

HIGHVOLT is a reliable project partner

Additional resources

Get in touch with us to get your personal login credentials to download papers with detail information.

Feel free to contact us!

- Dan Keller

- HIGHVOLT

Prüftechnik Dresden GmbHMarie-Curie-Strasse 1001139 DresdenGermany